braid to mono knots

Be sure the loops are forming right as you are starting to snug the knot. Also, a liberal amount of saliva helps too. I'll break one or two when I tie em with light lines too but eventually I'll get one that I cant break with my hands. What lb lines are you joining? If they are hugely different in diameter this will make for a hard knot. When I join 30lb Power Pro and 60lb or 80lb Flouro I'll have a few knots slip till I get a good and snug one. PP has a way of cutting things. Ive used PPro to cut a PVC pipe in a pinch. Try tying a "Bimini" in the braid then tying your Uni with the doubled up braid. I break very few knots when I do this and always prefer to double up the braid but sometimes its not really practical like when Im throwing lures. Hopefully my rambling helps you out some.

Use a 4 foot piece of jb 130 hollow to join them. Smaller and stronger then any knot.

splicing JBs 60-80lb lines will drive you mad being new to it. If you do decide to go that route it is a must to have the proper splicing needle, I like the http://www.charkbait.com/cs/cshL_Daho.h ... %20Needles again splicing hollow line under 130 can be very difficult.

Another option for ya... I like to run Sufix 832 braid to a short top shot of 130lb mono on my casted shark rigs. I use a 3-4 foot peice of 130 or 200 lb Jerry Brown for a connection sleeve, its very stream line and stronger then any knot. heres how

Some like solid braid over hollow core braid but still need to connect a mono top shot. i.e If you need to cast a top shot, braid to mono knots can be a real pain. If you just hate the idea of tying a knot in the middle of your line heres the option.

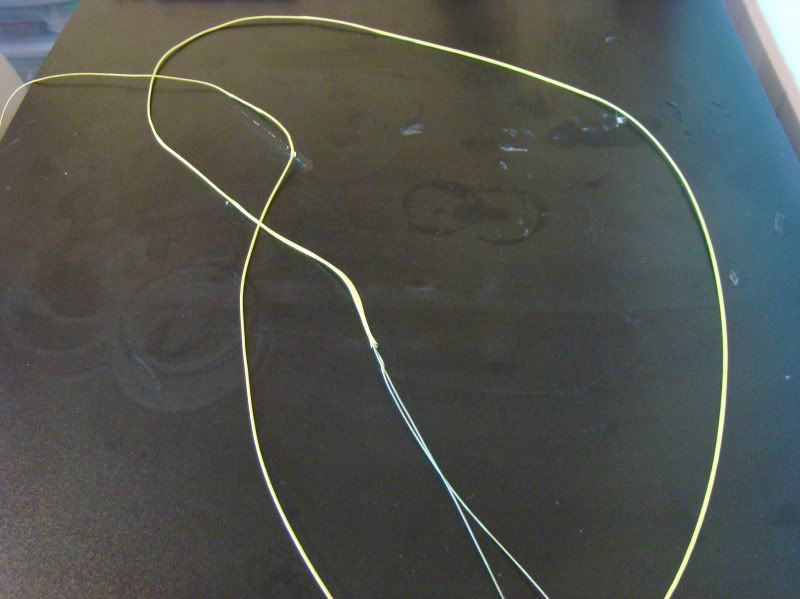

I take a 6-8 foot piece of jerry brown hollow core line and use it as the connection sleeve. Depending on the application but for example I will use 130 lb class heavy gear... Casted rigs I only use a short 3-4 feet sleeve of 130 Jb

First thing you need is the right tools. 1 hollow inline splicing needle for the size of your line. I like buying a needle bigger then needed... if your splicing 130lb mono the 150lb splicing needle works just fine. *note* the 150lb needle is extremely difficult to splice 130lb hollow, the needles outer diameter is to big. http://www.charkbait.com/cs/cshL_Daho.htm to get small spools of hollow core and the needles.

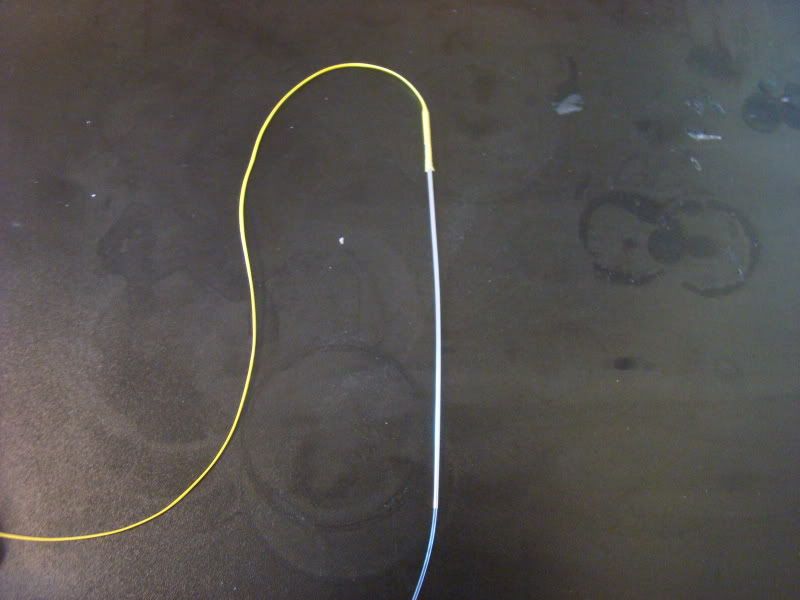

First thing I do is put a tapper on the tag end of the mono you are splicing in.

What this does is make the hollow core have better bite on the mono. The hollow core needs to be pulled tight and the faster it can get small the harder it bites.Now push the mono up into you splicing needle and insert the mono up in the hollow braid about 3-4 feet.

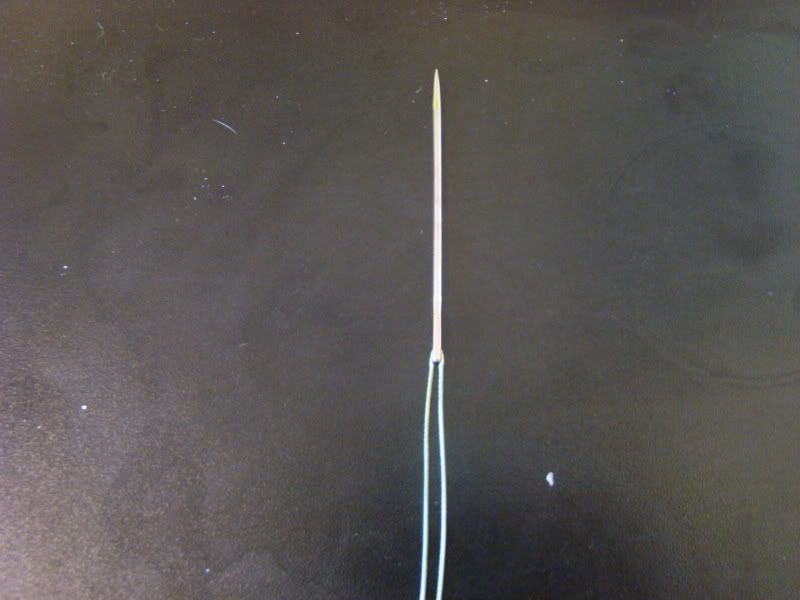

After you get to the 3-4 foot mark just push the needle out the side of the hollow braid and work the mono back down so its all inside the braid.Now for the solid braid. I use a store bought yarn needles for this or the daho needles. I take the solid braid thru the yard needle and double the braid back on itself creating a big loop. It should be about 3-4 feet long.

now insert the solid braid up in the hollow about 3-4 feet. You can butt the solid braid right up to the mono, but dont worry if there is space between it wont hurt a thing.

Once the yard needle is out take some snips and clip the end of the needle off so you can get the braid out. If you use the daho needles you have to be careful not to let the braid slide out of the needle before you get 3-4 feet in.

For the last step you need to serve the tag ends of the hollow braid. make sure to pull everything nice and tight before serving. I use a fly bobbin with wax thread but basic over hand knot or nail knots will work. You only need to do about and inch of the hollow tag, just serve right to the end of the hollow braid. If you serve on the hollow and right over onto the mono it will come undone. I used to serve over the whole connection spot 1inch on the hollow and one inch on the mono or solid braid but... when the mono stretches it gets smaller so it needs to pull back some and you cant stop it. What happens is it separates the serve causing it to come unraveled and weak. Just FYI even with out the severe it will not slip out. The serve is just to hold the tag ends of the braid from coming unraveled and help aid in the splice. The serves purpose is only to keep the jb from pushing back on the line while going thru the guides.

Last step is rub a little bit of glue on the serve to aid in it getting frayed up. This is my favorite glue

I use this connection for small windons on casted gear with 50lb solid braid and 60lb-200lb mono. the 130 and 200 lb hollow works fine and i only use a little 3 foot piece of hollow core.

I use this when making a heavy long windon like adding a section of 2 or 300lb mono on my top shot when fishing where abrasions are killer.

this connection also works on bad spots in your line. i.e. you just spooled a new top shot on your reel but the first drop you did, a little section got tore up bad. Cut the bad section out and splice it back together with this.It works and its strong. You might get nervous when you see it come off the reel but after some time of zero failures you will be 100% confident. I have become so confident in this splice that I have used it with less then a foot of splice and have yet to have a failure. I have tested on fish from 1000lb tuna to bait fishing a 30lb solid braid to 60lb lb shock leader spliced together with a 18 inch piece of 130lb Hollow.

I know it seems very difficult to do but once you do it and use a few times I promise you will love it. It can be done very quickly after you learn it.

Hope it helps.

Latest Post: Welcome Back -its been a while Our newest member: monstersharkman Recent Posts Unread Posts Tags

Forum Icons: Forum contains no unread posts Forum contains unread posts

Topic Icons: Not Replied Replied Active Hot Sticky Unapproved Solved Private Closed